- Applications

-

Products

-

Liquid Handling

- firefly Accelerate genomic research with innovative all-in-one, compact liquid handling

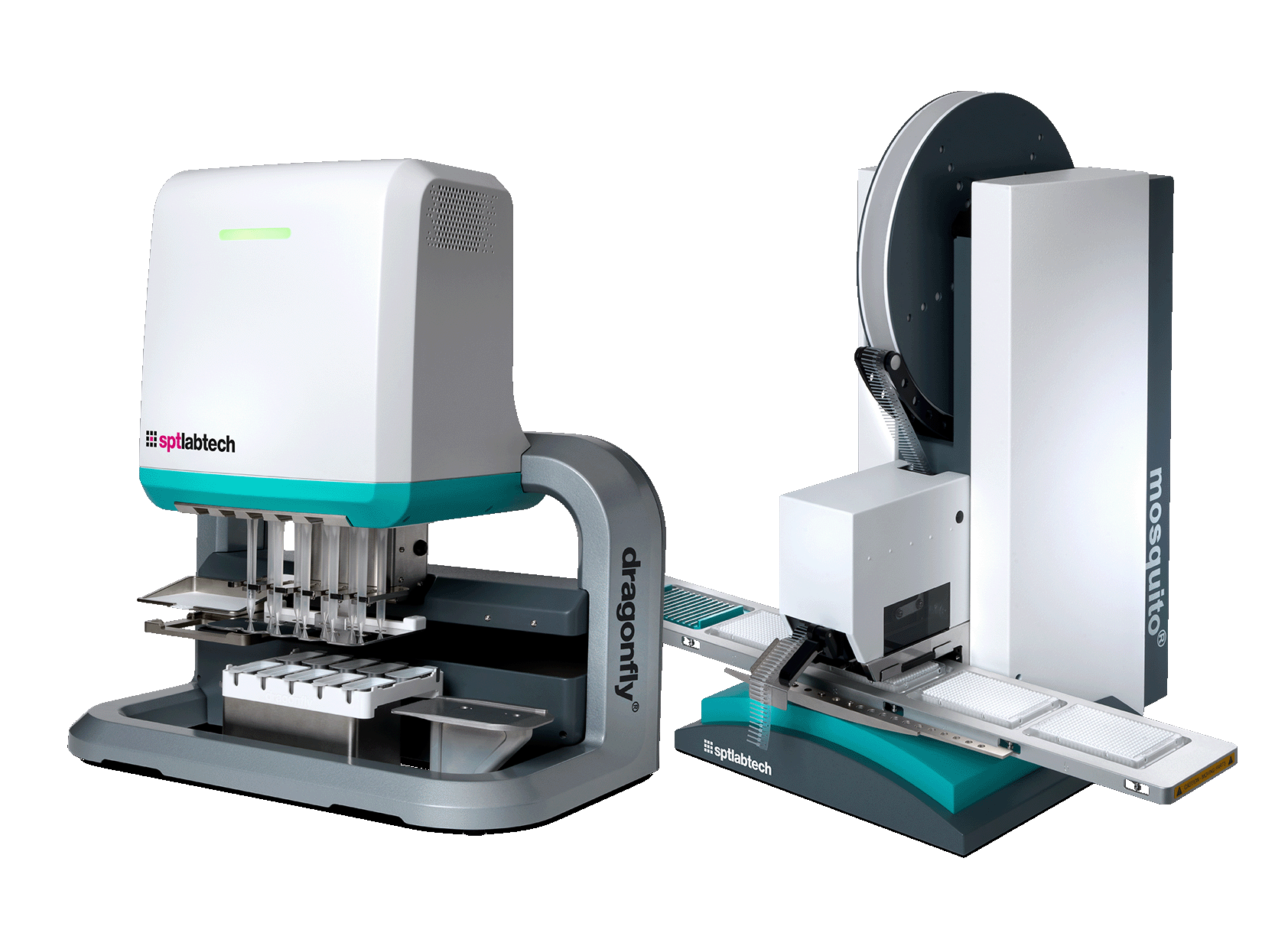

- mosquito Nanolitre liquid handling technology performs ‘traditional’ tasks at a fraction of the volume, and higher speeds

- dragonfly Delivers accurate and repeatable nanolitre to milliliter dispensing

- apricot Automated liquid handling instrumentation for convenient general use across your entire team

- Sample Preparation

-

Sample Management

- comPOUND A scalable, reliable, and secure compound management solution

- BioMicroLab Easy-to-use sample management automation instruments

- arktic Robust biospecimen storage and management down to -80°C

- lab2lab Novel sample and data transfer network system

- comPACT Reliable and efficient -20°C storage and retrieval has never been more accessible

-

Liquid Handling

-

About

- Company With a focus on liquid handling, sample preparation and sample management, our expert teams create state-of-the-art solutions that scientists and researchers can trust Culture We have one overarching mission: to work together to accelerate life science research. Through our innovative solutions and state-of-the-art tools, we believe we can make a real difference to human health Innovation From the initial prototype through to manufacturing, installation and beyond, we bring a problem-solving mindset and technical expertise to drive innovation Board Members Our Board of Directors are committed to driving the long-term success and sustainability of SPT Labtech, providing expert guidance and oversight to execute the company’s ambitious commercial strategy.

-

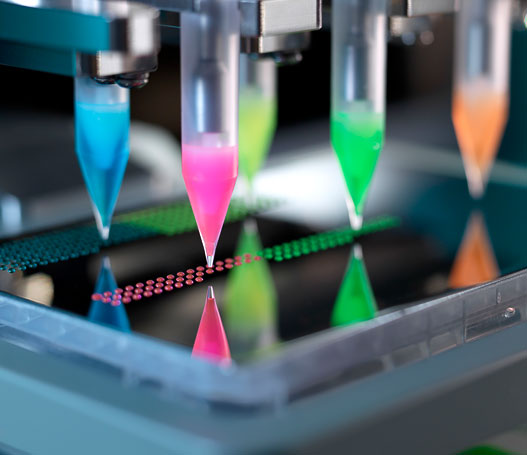

Positive displacement technology

.jpg) Novel positive displacement dispensing technology from disposable tips underpins our liquid handling portfolio of products

Learn more

Novel positive displacement dispensing technology from disposable tips underpins our liquid handling portfolio of products

Learn more

-

View all

Pneumatic tube transport

Pneumatic tube transport

.jpg) Harnessing the power of pneumatic technology, our innovative sample transport solutions deliver quickly and reliably between labs, analytical suites and even across sites hundreds of meters apart

Learn more

Harnessing the power of pneumatic technology, our innovative sample transport solutions deliver quickly and reliably between labs, analytical suites and even across sites hundreds of meters apart

Learn more

-

Knowledge Base

- Events & Webinars Meet the SPT team at events all over the globe and virtually via our webinars Blog Our latest blog posts feature trends in research, innovative techniques and new technology Resources Our wide range of insightful resources include videos, whitepapers, eBooks, application notes and more News Latest news from SPT Labtech globally

-

23 April, 2024

SPT Labtech supports life sciences startup growth by joining forces with BioLabs

Continue reading

SPT Labtech supports life sciences startup growth by joining forces with BioLabs

Continue reading

-

11 April, 2024

SPT Labtech Appoints Rob Walton as New Chief Executive Officer

Continue reading

SPT Labtech Appoints Rob Walton as New Chief Executive Officer

Continue reading

-

27 March, 2024

5 ways to mitigate biological sample integrity loss

Continue reading

5 ways to mitigate biological sample integrity loss

Continue reading

10

- Careers

Our innovative dispense technology offers a number of key technical advantages

- superior low volume dispense performance

- suitable for all liquid classes

- inherently reliable

- broad dynamic dispense range from a single syringe type & economical syringe usage

- compatible with deep well plates up to 44mm in height

- no risk of blocked ducts or nozzles

- developed in partnership with world-leading scientists, dragonfly discovery not only delivers exceptional performance, but also provides an optimal user experience to facilitate adoption into novel application areas.

Just walk up and use

With no calibration or daily maintenance requirements, setting up an experiment couldn’t be easier with these 3 simple steps. Select a protocol or set up a new experiment in our intuitive software package - fit positive displacement syringes and lay out reagents

click run to dispense into your plate of choice

Greatly improve assay robustness

From aqueous buffers, DMSO and PCR master mixes through to cells and even viscous basal membrane extracts: dragonfly discovery enables highly accurate and repeatable dispensing starting from just 200 nL, for robust assays and superior quality data.

Maximize precious reagents

Make your reagents go further with assay miniaturization. Whether working with 384- or 1,536-well plate formats, assay miniaturization is ideal to increase throughput, cut reagent costs and standardize workflows. Combined with fully recoverable, ultra-low dead volumes this approach ensures that users derive maximal value from their precious reagents.

Save time

Rapid plate fill times, programmable staggered reagent additions and minimal maintenance requirements allow scientists to spend their time on high value scientific tasks such as planning and analyzing experiments.

Flexible configuration

dragonfly discovery is based on a modular design that works flexibly around your workflow. Choose from 3, 6 or 10 independent positive displacement dispense heads, in either standard or deep well block format, to suit your application and throughput requirements. Setup as a standalone benchtop unit, or integrate into your workcell of choice. The autofeed reservoir reagent module increases reagent capacity for high volume bulk filling tasks and enables extended walk away time.

Suitable for low or high throughput assays

Compatible with any SBS plate format up to 44mm in height across 96-, 384- and 1,536-well plates. Highly controlled dispensing into 96- or 384-well PCR plates for sensitive genomics applications, as well as rapid bulk dispensing into deep well blocks or racked tubes.

We’re revolutionizing liquid handling

dragonfly discovery enables accurate and repeatable nanolitre to milliliter dispensing, every time, irrespective of liquid viscosity or environmental conditions.

- Customized to suit your application and throughput

- Positive displacement dispensing

- Volumetric performance

- Our software

- Integration

Customized to suit your application and throughput

- 3,6, or 10 independent dispense heads

- choose between standard or deep well plate compatible configurations

- synchronize dispense heads to increase throughput, or choose independent head control for reagent flexibility

- autofeed reservoir module

- automation package

- dedicated genomics accessories that are fully compatible with our mosquito liquid handlers

- assay development software

Positive displacement dispensing

Our true positive displacement syringes are controlled by independent dispense heads located inside the instrument.

Key features:

- 200 nL – 4 mL dispense range

- liquid class agnostic, with no calibration requirement

- non-contact dispensing, for minimal syringe consumption

- no cleaning or maintenance requirement

- zero chance of blocking or clogging

Learn more about positive displacement liquid handling and dispensing.

Built for pure performance

- outstanding accuracy: <5% error at 1 µL (Artel multichannel verification system)

- unrivalled precision: <5% CV at 1 µL

- minimal head to head variation: <5% CV across all dispense heads

Our software

The dragonfly software is as focused on usability as it is on functionality:

- highly visual, easy to use UI

- flexible sequencing of liquid additions

- automation of time point experiments, allowing for maximum walk-away time

- saving and loading of full experiment setup data, for full reproducibility

The dragonfly designer software is a complimentary software package designed to specifically meet the needs of assay development scientists:

- intuitive definition of multiple concentration gradients, both linear and high dynamic range n-fold

- definition of technical replicates and controls

- calculation of all well dispense volumes, as well as overall reagent requirements

- open source .CSV file output that loads directly into the dragonfly software package

Versatile workflow integration

The dragonfly software includes a fully documented API for 3rd party integration with a wide variety of other laboratory instrumentation, including robotic plate handlers, stackers and bulk liquid handlers, to achieve walk-away operation in many application areas.

dragonfly Citations

Technical Specification

Scroll to view more information

| Instrument variants | 3, 6 or 10 dispense heads in either standard or deep well plate compatible configurations | Dispense volume range | 200 nL – 4 mL |

| Bulk dispense speed starting from | 30 seconds per 96 90 seconds per 1,536 well plate |

Dead volume | 75 or 240 µL recoverable dead volume, depending on reservoir type |

| Primary SBS plate formats | 96, 384 and 1,536 well microplates. Deep well blocks or racked tubes up to 44 mm in height. | HTS modules | autofeed reservoir module, fully documented API |

| Accessories | PCR plate adapter, chilled reservoir blocks, incubation stage lid | Dimensions (W x D x H) | 600 mm x 433 mm x 635.5 mm 23.6 in x 17 in x 25 in |

| Weight | 46 kg/ 101.4 lbs |

Consumables

Order your dragonfly discovery syringes and other consumables using our online store.

Dynamic duo for genomics miniaturization

mosquito® & dragonfly® for genomics miniaturization

Volume miniaturization with automated liquid handlers solves throughput and cost challenges, enabling genomics researchers to process more samples and make savings on reagent use.

Our 'dynamic duo' – the combination of mosquito's highly accurate positive displacement pipetting with dragonfly's non-contact, nanoliter-to-milliliter dispensing – offers proven workflow solutions with a growing list of over 40 NGS methods miniaturized.